What is 3D Printing in Dentistry?

Advantages of 3D printing for dental use

Role of CAD/CAM Technology in 3D Printing

Challenges and Limitations

Some of the most significant problems and limitations are as follows:

- For smaller dental offices or labs, the initial cost of purchasing 3D printing hardware and software might be prohibitive.

- Although there are several dental-specific 3D printing materials available, their quality and range might differ. It is essential to guarantee that materials are robust, biocompatible, and compliant with regulations.

- Dentists must abide by stringent rules and guidelines to ensure the safety of patients and the highest level of care. It might be difficult to ensure that dental parts produced through 3D printing adhere to these specifications.

- A certain amount of technical knowledge is necessary for dental 3D printing to be effective. Training may be required for dental workers and professionals to use 3D printers and software efficiently.

- Some 3D-printed dental parts need to be cleaned, cured, or polished after printing, which might complicate and extend the manufacturing cycle.

Steps @ Royal Dental Clinics for 3D Printing Process

Future Trends and Advancements

Cost Considerations and Return on Investment

Additive Manufacturing at Royal Dental Clinics

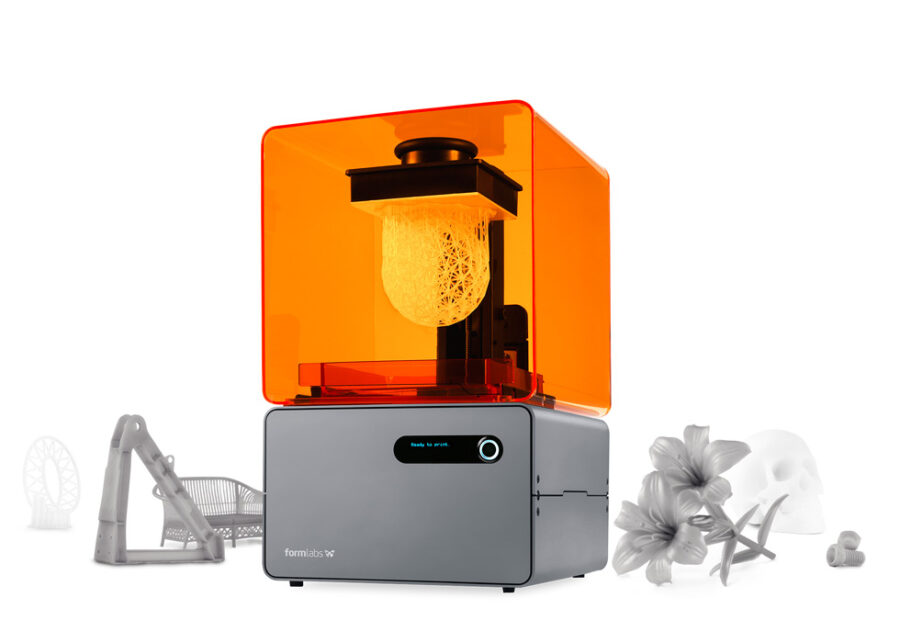

Additive manufacturing or 3D printing at Royal Dental Laboratory allows to produce dental crowns very quickly. This process can be done by the person scanning and planning itself. It makes possible to get a scan of the patient’s teeth, model it and to directly print the dental crown. Royal Dental Clinics plans patient cases and then prints the design via Phrozen. Dental 3D printing is a key at Royal Laboratory for modern dentistry solutions, as it really helps for customisation and accurate planning. Additive manufacturing also has an important role in dental implant surgery including zygomatic implant surgeries.

It is actually possible to create a 3D model to replace a missing tooth with more accuracy than with traditional methods. We can even produce crowns very quickly by scanning the patient’s teeth, modelling it and printing the crown.