The Computer-Aided Design and Computer-Aided Manufacturing (CAD-CAM) revolution has changed the way dental laboratories work. This powerful technology has allowed for more accurate and efficient processing of dental prosthetics, from crowns and bridges to implant-supported restorations. With this guide, you will learn the fundamentals of CAD/CAM, the various types of systems available, and the different steps involved in the process. Get ready for a comprehensive overview of how CAD/CAM is revolutionizing dental laboratories. Each type of CAD/CAM system has its own advantages and disadvantages, and the choice of system will depend on the specific needs and preferences of the dental lab.

Types of CAD/CAM in Dental Lab

Intraoral scanners: These systems use a handheld device to capture digital impressions of a patient’s teeth and surrounding oral structures. The scanned data is then used to create 3D models of the patient’s teeth, which can be used to design and manufacture restorations such as crowns, bridges, and dentures.

Laboratory CAD/CAM systems: These systems are used by dental labs to design and manufacture restorations. The lab technician uses specialized software to design the restoration, which is then milled or 3D printed from a block of ceramic or composite material.

Chairside CAD/CAM systems: These systems allow dentists to design and fabricate restorations in their office, without the need for a dental lab. The dentist uses a computer to design the restoration, which is then milled from a block of ceramic or composite material.

In-lab scanners: These systems use a tabletop scanner to capture digital impressions of a patient’s teeth and surrounding oral structures. The scanned data is then used to create 3D models of the patient’s teeth, which can be used to design and manufacture restorations.

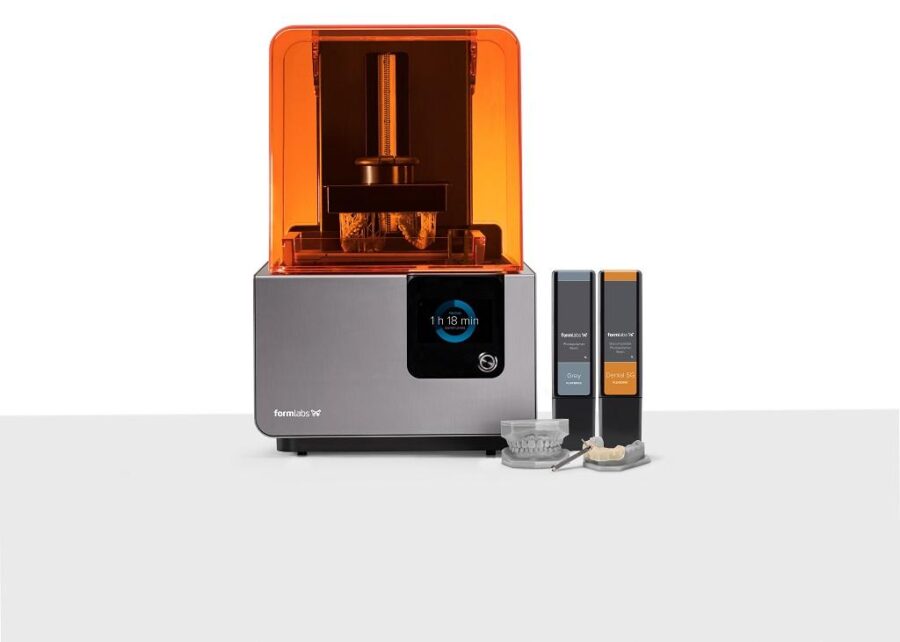

3D printers: These systems use a digital file to print a physical object from a variety of materials, such as ceramics or plastics. In dental labs, 3D printers can be used to create models of patients’ teeth or to manufacture restorations such as dentures or orthodontic appliances.

Benefits of Using CAD/CAM in Dental Clinic

Overall, CAD/CAM technology can help dental clinics provide more efficient, precise, and cost-effective treatment to their patients while also improving the patient experience.

Accuracy: CAD/CAM systems are highly accurate, which leads to better-fitting restorations and improved clinical outcomes.

Speed: CAD/CAM systems can significantly reduce the time required to design and manufacture restorations, which allows dental clinics to provide faster treatment to their patients.

Precision: CAD/CAM systems can create highly precise and intricate restorations that may not be possible with traditional techniques.

Cost-effective: By reducing the need for manual labor and multiple appointments, CAD/CAM systems can be a cost-effective solution for dental clinics.

Patient comfort: CAD/CAM systems can eliminate the need for messy and uncomfortable impression materials, which can improve the patient experience.

Improved communication: CAD/CAM technology allows for improved communication between the dental clinic and the dental lab, which can lead to better collaboration and faster turnaround times for restorations.

Customization: CAD/CAM systems can create highly customized restorations that meet the specific needs of each patient.

Process of CAD/CAM in Dental Lab | Dentistry

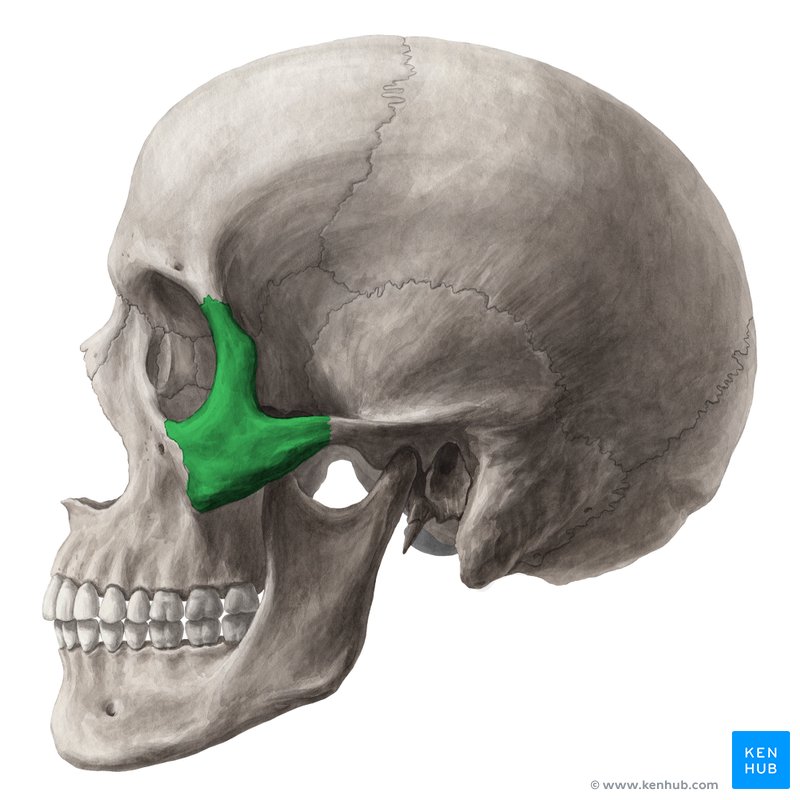

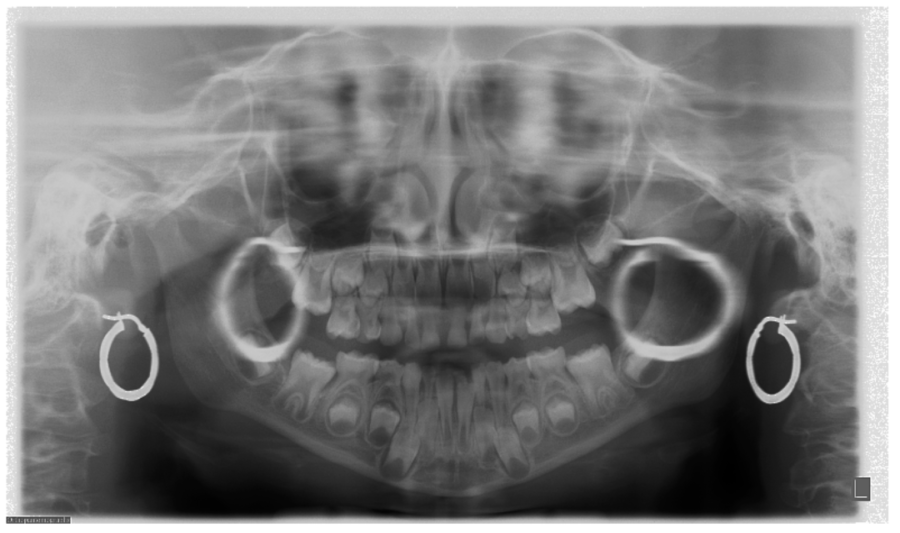

Preparation: The first step in the process is to prepare the patient’s teeth and surrounding structures for the restoration. This may involve removing decayed or damaged tooth material, preparing the teeth for crowns or veneers, or taking impressions of the teeth.

Scanning: Next, a digital impression of the prepared teeth is taken using an intraoral scanner or a tabletop scanner. The scanner captures the shape and contours of the teeth and surrounding structures, creating a digital 3D model.

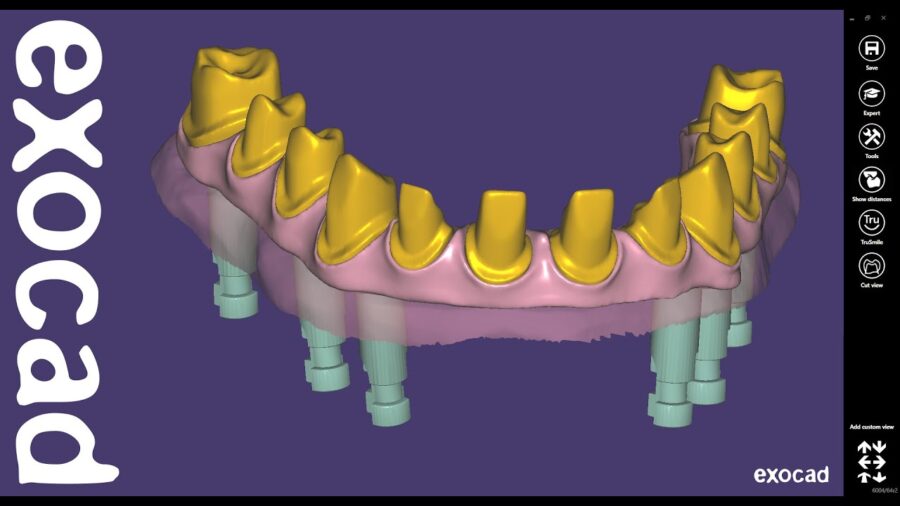

Design: The digital 3D model is imported into CAD software, where the dental technician can design the restoration. The software allows the technician to customize the shape, size, and color of the restoration, ensuring a precise fit and a natural-looking result.

Manufacturing: Once the restoration has been designed, the CAD software generates instructions for the CAM (computer-aided manufacturing) system. The CAM system then mills or 3D prints the restoration from a block of ceramic or composite material. Depending on the type of restoration, the manufacturing process may take anywhere from a few minutes to several hours.

Finishing: After the restoration has been manufactured, it is removed from the milling or 3D printing machine and undergoes finishing processes such as polishing or glazing. This ensures that the restoration has a smooth, natural-looking surface and fits properly in the patient’s mouth.

Delivery: Finally, the restoration is delivered to the dental clinic, where it is cemented or bonded to the patient’s teeth. The patient may need to return for follow-up appointments to ensure the restoration is functioning properly and to address any issues that may arise.

CAD-CAM Technology in Dental Laboratories

CAD CAM technology has become increasingly popular in dental laboratories, with most laboratories now utilizing some form of CAD CAM system. The most common type of CAD/CAM system used in dental laboratories is the 3D system, which makes use of both CAD and CAM software to design and produce prosthetics.

CAD/CAM systems are used for a variety of purposes in dental laboratories, from the fabrication of crowns and bridges to the production of dental implants. They are also used for the design and production of digital dentures, which are dentures that are designed and produced using CAD-CAM technology.

Finally, CAD-CAM systems are also used for the production of 3D-printed prosthetics. These prosthetics are designed using CAD software and then 3D printed using specialized 3D printers.

3D Printing for Dental Prosthetics

This is another technology that is being used in dental laboratories to create prosthetics. 3D printing technology is used to create prosthetics that are more precise, accurate, and customizable than those created with traditional methods.

The process of 3D printing a prosthetic begins with a digital design, which is created using CAD software. This design is then sent to a 3D printer, which uses special materials and techniques to create the prosthetic.

One of the benefits of 3D printing is its ability to produce highly accurate prosthetics with minimal manual input. This makes it ideal for the production of complex prosthetics, such as implant-supported bridges and digital dentures.

Royal Dental Clinics | Maxillofacial CBCT with CAD CAM | Dental lab near me in Mumbai

Choosing the Right CAD-CAM System for Your Dental Lab

When choosing a CAD-CAM system for your dental laboratory, it is important to consider your needs and budget. If you are looking for a basic system for the design and production of crowns and bridges. Then a 2D system may be sufficient. On the other hand, if you are looking for a system capable of producing complex prosthetics, Such as implant-supported restorations and digital dentures, then a 3D system may be more appropriate. Finally, if you are looking for a system that can produce 3D-printed prosthetics, then you may want to consider a system with integrated 3D scanning and printing capabilities.

Conclusion

CAD-CAM technology has revolutionized the dental laboratory industry. Allowing for the design and production of prosthetics with greater speed and accuracy than ever before. This guide has provided a comprehensive overview of CAD-CAM systems. The benefits of using CAD/CAM The process of CAD/CAM CAD-CAM technology in dental laboratories, digital dentures, and prosthetics with CAD-CAM 3D printing for dental prosthetics and CAD/CAM software And choosing the right CAD-CAM system for your dental lab With this knowledge, you can make an informed decision about which CAD/CAM system is best for your laboratory.

Advanced technology and equipment are available at the Royal Dental Clinics Lab. Including a 5-axis milling machine, a sintering furnace, and 3D printing. Royal Dental Clinics Lab has created seamless procedures for planning and designing. And the production of dental crowns using cutting-edge tools and technology from across the world.